Displacement Pumps

With our diverse standard and high performance pumps we are able to serve all your needs and respond to any challenge. Our Rotierende Verdrängerpumpen are robust, self-priming and have running dry running capability.

- Pressures up to 120 bar

- Flowrates from 1,5 l/h to 300m3/h

- Viscosity up to 1.400.000 mPas

- Temperature up to 450°C

- Efficiency up to 92%

- Suction lift up to 8m

- Solids up to 90%

INDUSTRIES

APPLICATIONS

PRODUCTS

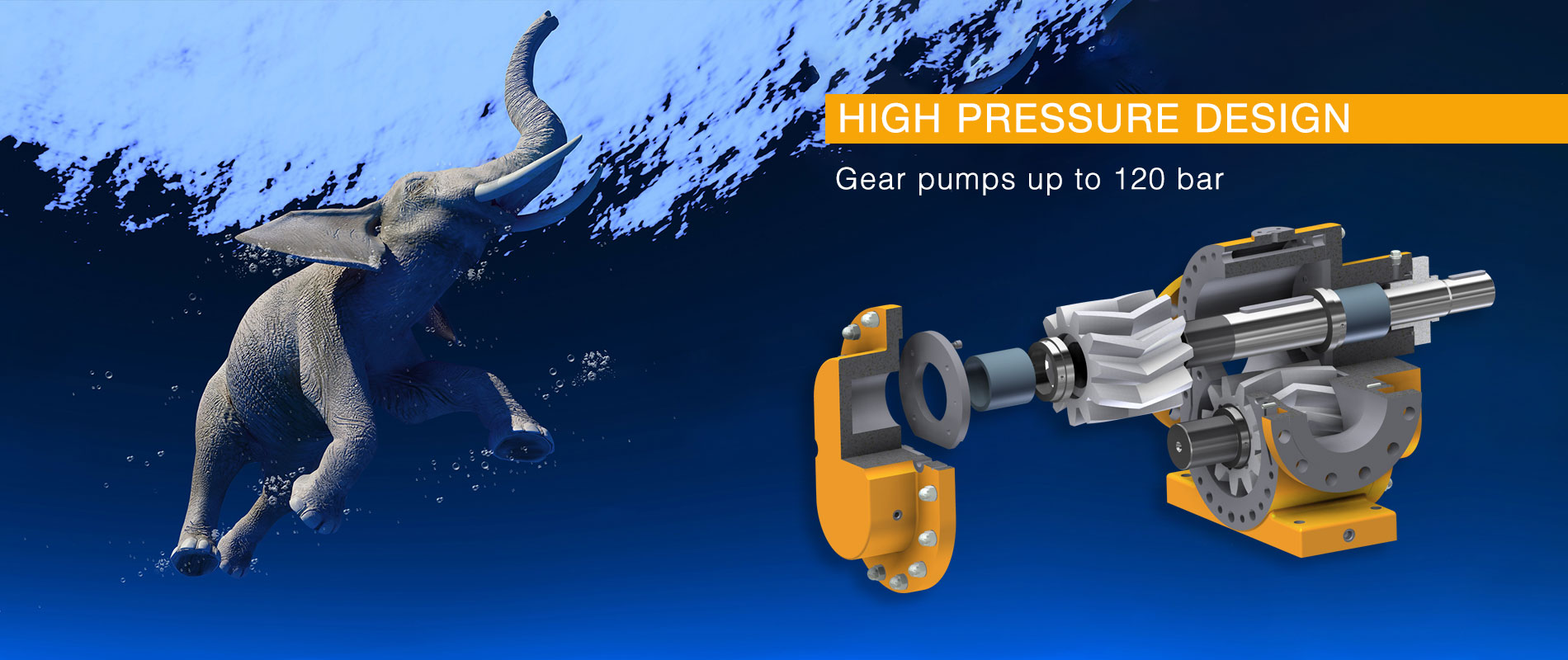

GEAR PUMPS

High performance gear pumps

On demand, we can provide external gear pumps which are API, ATEX, TR-CU 10, TR-CU 12 and TA Luft compliant.

With our diverse standard and high performance gear pump range we are able to serve all your needs and respond to any challenge…

INTERNAL GEAR PUMPS

Standard gear pumps

On demand, we can provide external gear pumps which are API, ATEX, TR-CU 10, TR-CU 12 and TA Luft compliant.

With our standard internal gear pumps we offer a cost effective alternative solution to cover standard applications…

ROTARY LOBE PUMPS

For all high viscosity liquids with or without solids

On demand, we can provide external gear pumps which are API, ATEX, TR-CU 10, TR-CU 12 and TA Luft compliant.

With our diverse standard and high performance pumps we are able to serve all your needs and response to any challenge…

MODULAR PUMP DESIGN

PUMP CONFIGURATOR

New: The Online

Pump Configurator

Fast and Easy Pump Setup

Allows you to properly configure, calculate and select a Zeilfelder Pump.

Combine the used liquid, its viscosity, the requested working pressure, temperature etc… and the configurator will choose the right pump to cover your needs.